using the field hardness test|can hardness testing be done : companies Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for . Zeusart - Rule 34 World

{plog:ftitle_list}

Resultado da 2 de ago. de 2022 · Economia. Como Brasil pode reduzir a pobreza no próximo governo, segundo Banco Mundial. No começo dos anos 2000, .

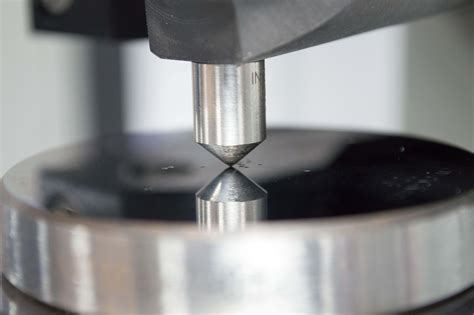

The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value is .

In the field of hardness testing, different main loads (test forces) are used based on the application. Depending on how high the main load is that is applied to a specimen during the hardness test, within ISO a differentiation is made .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for . In the specific failures and equipment examinations discussed in this article, field hardness tests gave the most insightful information for assessing challenging material anomalies compared to other laboratory and .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed.Hardness Testing. Discover the intricate world of hardness testing in materials engineering. This comprehensive guide delves into the definition, standards, procedure, and vital . Hardness testing is one of the most popular, reliable and yet diversified material testing methods. Most hardness testing is performed by using the Rockwell, Brinell or Vickers .A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by .

material hardness test

More simply put, when using a fixed force (load)* and a given indenter, the smaller the indentation, the harder the material. Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general characterizations 1.Material CharacteristicsHowever, these tests require specialized equipment and are not as convenient for field use as the Mohs scale. Vickers Hardness Test: In contrast to the Mohs Scale, which relies on scratching minerals, the Vickers test measures hardness based on the indentation made by a sharp diamond pyramid.Hardness, Iron, and pH test kit provides an easy to use, cost effective way to determine the quality of your water; includes color . Kit contains all required reagents and apparatus in a rugged carrying case for analysis in the field. .

how hardness testing works

Electrolytic polishing equipment for all your needs, from non-destructive testing in the lab to mobile solutions for use in the field and electrolytes for virtually any application. . the lower the load you use in the hardness test, the more factors that need to be controlled to ensure an accurate conclusion of the hardness test.The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness.

Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. . ② The method is simple, nondestructive and suitable for field inspection; ③ The physical meaning is not clear, and it is difficult to design quantitatively. (2) Relationship between hardness and strength.Figure 23.4 Schematic of the Rockwell indentation process using a diamond brale Indenter. The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your .

The Rockwell Hardness Tester has many different scales depending on the application of the tester on different materials. There is a total of 30 Rockwell hardness scales available to use for hardness testing and hardness value. The Rockwell Regular Scales Testing use a preload of 10kgf and a major load of 50kgf, 100kgf, or 150kgf. When rockhounding, the hardness test is simple to administer at home or in the field. One key to identifying mineral species is to test its hardness. Mineral hardness tests can be performed at home or on a rockhounding field trip. There are necessary tools for express hardness testing: A fingernail, a Cooper coin (penny or 1,2.5 cents euro), a . Steps for Performing the Mohs Hardness Test . Find a clean surface on the specimen to be tested. Try to scratch this surface with the point of an object of known hardness, by pressing it firmly into and across your test specimen.For example, you could try to scratch the surface with the point on a crystal of quartz (hardness of 9), the tip of a steel file (hardness .

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.Field Hardness Testing 4 Your esource for Safer Fields Brought to you by the Sports Turf Managers Association and its charitable Foundation, The SAFE Foundation ph. 1-800-323-3875 www.stma.org Additional practices that can help alleviate surface3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Rockwell hardness tests are the most common type of hardness test available, and for good reason: it’s an incredibly fast and reliable method to determine the hardness of metals, alloys, and plastics, when compared to other methods. In the test, a diamond cone or hardened steel ball indenter is forced into the material being tested with a . American Education Hardness Collection with Test Kit Rating Conclusion. To wrap it up, the Mineral testing kit (Amazon link) is the industry and Rockhound premium standard because it is exact and easy to carry with .Here's a step-by-step instruction to guide you through a standard hardness testing procedure, in this case, we'll use the commonly used Rockwell hardness testing method as our guide: Selection of an appropriate scale: Different testing scales (e.g., Rockwell B or C, etc.) are designed for materials of varying hardness.

Melting Point Tester fabrication

Why hardness testing? In manufacturing applications, materials are primarily tested for two reasons: either to research the characteristics of a new material or as a quality check to ensure that the sample meets a particular specification. .

The Mohs hardness scale rates the hardness of minerals based on their ability to scratch softer ones. The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn’t perfect, but it’s a great tool for quick identification of rocks in the field. Understanding Vickers’s Hardness Test. I use Vickers’ Hardness Test which can be used across different materials thereby enabling me identify material’s level of brittleness.This involves pressing the diamond pyramid indenter with square base and an angle of 136 degrees together with the opposing faces into the surface of a sample.Hardness testing using the MIC 20 in combination with the test support MIC 227 and a UCI probe in the heat-affected zone (HAZ) of a weld. Fig. 2: Hardness testing with a rebound hardness tester (DynaMIC) on the drive wheel of a large hydraulic excavator. Fig. 3: Hardness testing using the DynaPOCKET on the chain of an open-pit mining excavator .

work and as an indication of the coating’s performance; but also as a field test during post-application inspection. The pencil hardness test can be completed free-hand using the Elcometer 3080, which includes a set of 14 pencils (grades 6H to 6B), two specialised pencil sharpeners, and an abrasive paper block to prepare the pencil for testing.

A material’s functional integrity and strength can only be determined through material testing. The Leeb Hardness Test emerges as a valuable tool for engineers in this field. For engineers seeking to assess the hardness of metallic materials, this test emerges to be the most versatile, rapid, and portable option. Demystifying the Leeb . The Durometer Hardness Test serves as a vital quality control tool, allowing for real-time assessment during the production process. . in identifying the material that best meets the required hardness specifications and is well-suited for the intended use. Research and Development: In the field of material science and research, the Durometer .

A full selection of hardness testers, testing machines, testing equipment and accessories for Vickers, Knoop, Brinell and Rockwell hardness testing from Struers, the world’s leading materialographic and metallographic equipment supplier.

In order to test the hardness of a metal, the test measures the metal’s resistance using a penetrator. A penetrator is non-deformable and is ball or cone-shaped. The hardness test determines the depth that the ball or cone sinks into the metal. Specific loads are used for each kind of hardness testing. General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications.

unknowns. The galena will have a hardness of about 2.5 and the topaz will have a hardness of 8. Students now have some standards for doing hardness field tests and, if they can recognize quartz and feldspar in the field, they have some additional known hardness standards to use. Special Safety Procedures:

hardness testing standards explained

5 de jan. de 2024 · Our investigation has shown that a 200% deposit bonus is an incentive for players when they make a qualifying deposit. An online casino will match the amount of money you put down by 200% when you deposit the minimum amount. This is a huge incentive bonus, as most casinos offer a 100% match deposit.

using the field hardness test|can hardness testing be done